Harbor Castings Inc. • 2508 Bailey Rd. • Cuyahoga Falls, OH 44221 • Ph: 330-499-7178 • Fax: 330-499-2018

Why Choose Investment Castings

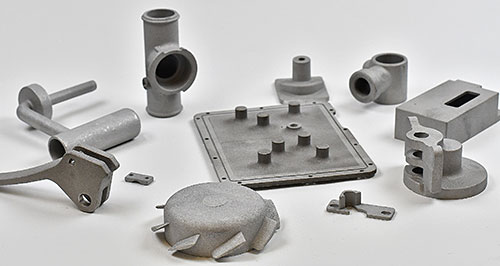

Durable Castings for a Fraction of the Cost

From concept to casting, we’ll help you translate your designs into durable, high-strength steel, aluminum, brass, or bronze parts, fast – usually within 6 weeks.

In the process, you’ll get design flexibility unparalleled by any other manufacturing methods – eliminate machining, welding, and fabrication operations; choose from a range of over 100 alloys to obtain precisely the properties needed.

Best of all, you’ll save – tooling and per-part costs are typically fractions of what you’d pay using any other processes.

A Harbor Investment Casting Will Deliver

- Precision: +/- .005 inch per inch and closer

- Good Surface Finish: 125 RMS or better

- Consistent Quality: no die wear, minor variation casting to casting

- Economical Alternatives: eliminate machining and assembly operations

- Wide Range of Sizes & Quantities: an ounce to thirty pounds, ten parts to millions

- Material & Design Flexibility: over 100 ferrous and non-ferrous alloys, endless shape possibilities

Harbor Castings Will Provide:

- Timely quotes

- Parts at economical prices

- Quality craftsmanship on your parts

- On-time delivery

- Friendly customer service

- Commitment to meeting our customer’s needs

- No voicemails — always a live voice

The Investment Casting Process

Investment castings are a fantastic way for Small to Medium-sized businesses to get affordable castings within a fleeting time frame. These steps create quality parts from start to finish.

1. A toolmaker builds a precision aluminum die to make wax replicas of the part, called patterns.

2. Molten wax is injected into the die cavity; the resulting pattern is removed after it solidifies.

3. From one pattern to as many as two hundred are wax welded to a wax runner to form a cluster.

4. The cluster is dipped repeatedly in liquid binder and ceramic powder to build up a shell mold.

5. The mold is placed in an autoclave to melt out the wax, then in a furnace to harden and preheat it.

6. Molten steel is poured into the heated mold and solidifies to form a cluster of castings.

7. The mold material is removed from the cluster, and the parts are sawed off from the runner.

8. The parts are finish-ground, deburred, and sent for secondary operations such as heat treating.

9. Each part is inspected and shipped on time – guaranteed to meet your specifications.

Harbor Castings Inc. • 2508 Bailey Rd. • Cuyahoga Falls, OH 44221 • Ph: 330-499-7178 • Fax: 330-499-2018

© Harbor Castings Inc. • All rights reserved. • Site design: Design-2-Part Web Design